Company ‘Milandr’ which is located in Zelenograd,

a Russian Silicone Valley,

produces electronics for Russian world-famous weapons.

This is not a secret factory with checkpoints and armed

security guards… so let’s check it out!

The company was founded in the 90s and up to 2003 it had been reselling microchips.

Later, however, they decided that, along with reselling, the company needed to have

its own microchip research and development or R&D.

There are four types of microchips. The first one is commercial.

It is also the easiest to make because the market has rather low requirenments for

this type of microchips (they have to work at room temperature, that’s it).

Requirenments for industrial microchips and military microchips are stricter

and the top class is space microchips which are used in space.

Apart from the military microchips market, the company works mostly in,

‘Milandr’ also produces microchips for GLONASS satellites and develops i

ts commercial sector. One of their reserches is aimed at developing tachograph

speed pickups which allow to measure the time haulers has been working for

to lower the risk of a car accident. ‘Milandr’ also collaborates with medical

institutions installing their devices in hospitals of the city.

However, the main customer of ‘Milandr’ remains Russian Military-industrial

complex and the company is very proud of the fact that its microchips can be

found in new Russian fighters and air defence systems.

The 100-million dollar ‘military’ microchips market of Russia is represented

by Russian and Byelorussian companies and ‘Milandr’ having over

400 customers accounts for as little as 6 million dollars.

There are three stages of the production process:

1. The company’s engineers develop a microelectronic device.

2. They pass the engineering design documentation to one of the

outsourcing companies which make silicone wafers.

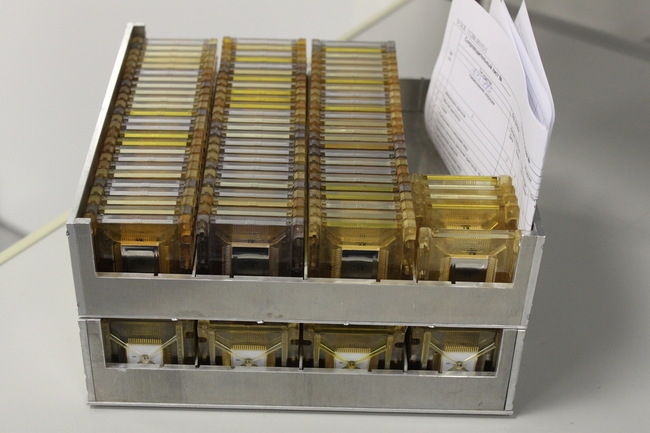

3. Silicone wafers get delivered back to the company to undergo

dicing, heremtic sealing, testing, marking, etc.

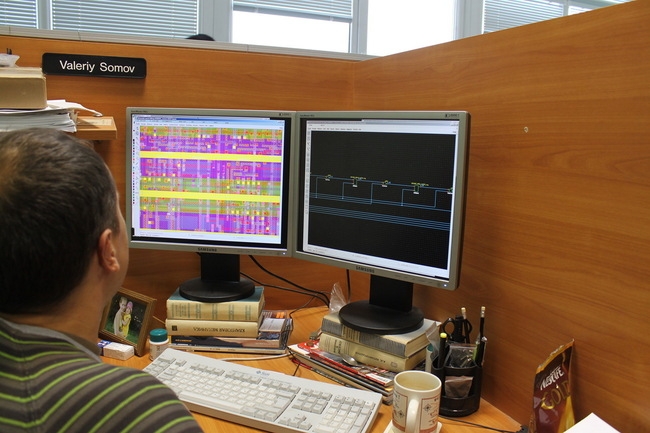

This is where the microchip starts its life, in the integrated

microcircuit developing center.

By the way, the company develops microchips

for both domestic market and export.

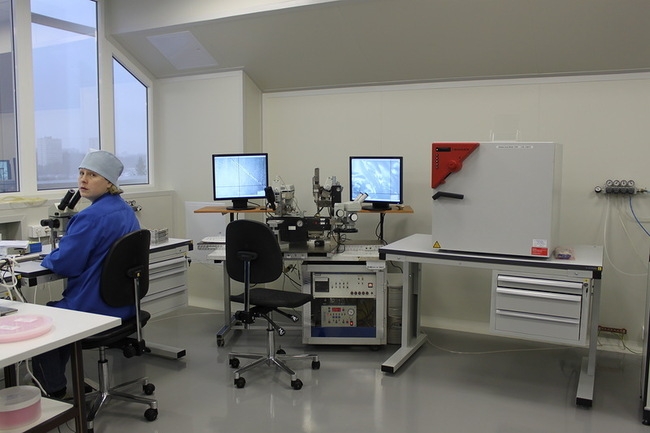

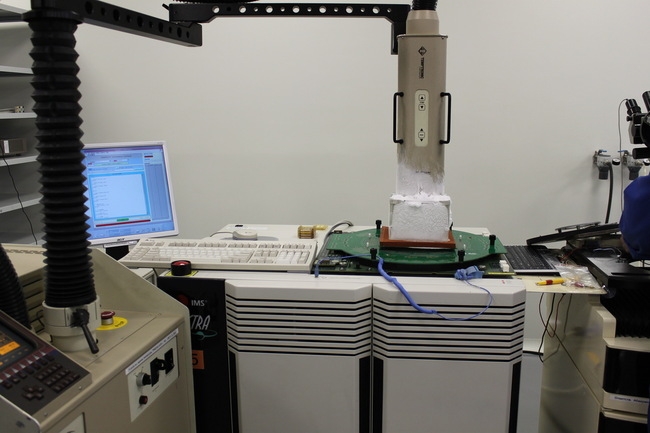

This is a room where they test their produce to receive a certificate.

It is equipped with up-to-date equipment and almost everything i

s automated. We’d better go to the production department where

they cut wafer substrates into crystals and do other interesting things.

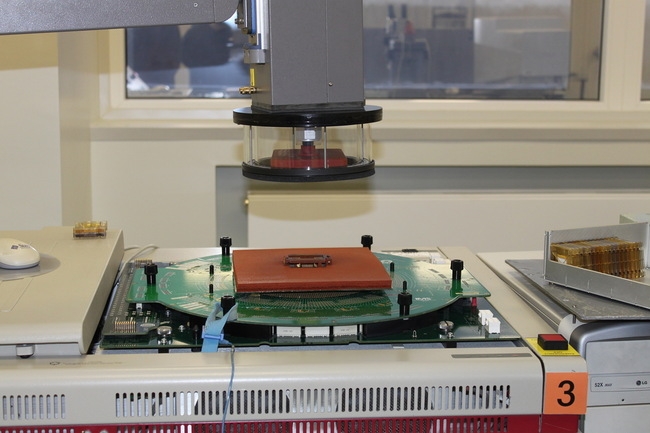

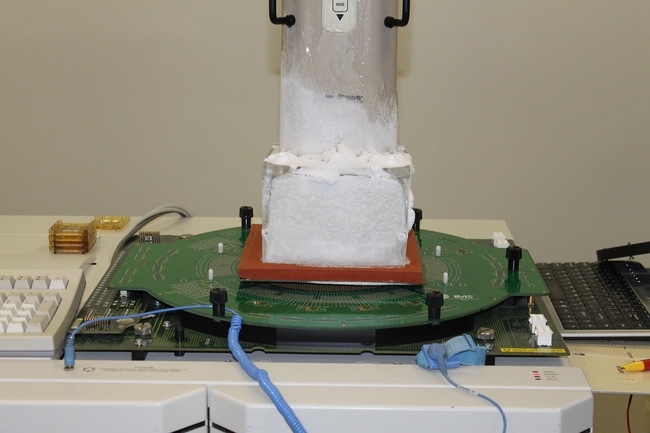

Now they have to test the crystals. Since this is going

to be ‘military’ microchips, they must meet most

stringent requirements.

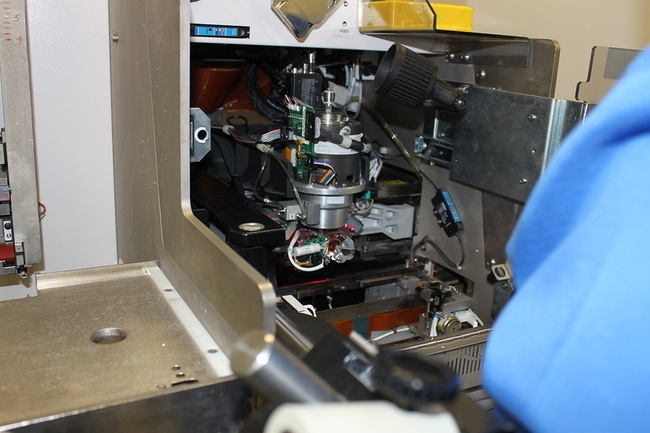

This is an automated semiconductor wafer prober.

There are two of them at the company.

A good shot!

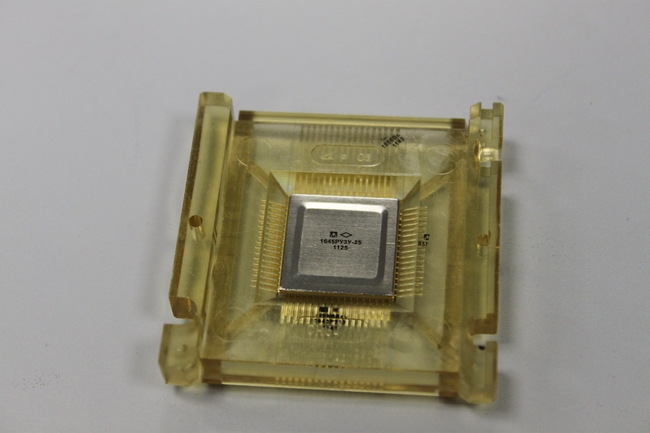

This is a finished product, a 512 Kbyte microchip. It just looks

like those which were installed in computers back in 1998. In fact,

this microchip can work under any conditions that is why

it costs almost 300$ apiece!

Isn’t it amazing that these small devices ensure

peaceful skies over our heads?

Location: Zelenograd

via sdelanounas.ru

No comments:

Post a Comment